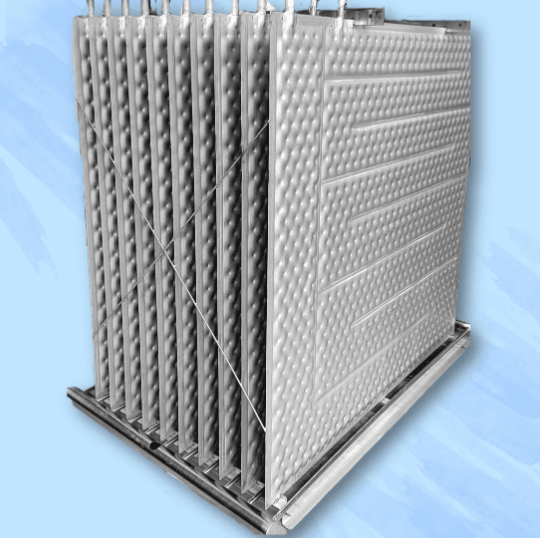

Pillow plates

Product Video

Advantages

- Open system, the surface of the heat exchanger plates is easy to clean and maintain.

- Different materials such as SUS304 and SUS316 can be selected to meet specific needs.

- Working pressure up to 30bar, meeting the pressure requirements of most heat exchange applications.

- The pressure is small internal of the heat exchanger system, meeting the fluid heat transfer requirements.

- Made of stainless steel plate, high temperature resistance and long service life.

- Special flow channel design, high efficiency of heat exchange.

Features

- Used in many ways for the industrial cooling or heating of your products.

- Heat exchanger plate is made of stainless steel, no matter whether it is clean liquid (gas) or contaminated liquid (gas), it does not affect its performance.

- When as heat exchanger plate of cooling, even if the surface of the plate is frozen, there is no need to worry about the freezing blocking and burst.

- Depending on applications, immersion model or fall film model is optional.

- Wide range of applications, can be used as evaporators and condensers in refrigeration systems, as well as liquid-liquild heat exchange system or gas-liquild exchange system.

- According to different needs, it can be designed for heat recovery or cold recovery system to maximize energy saving and reduce cost.

Project cases

Heat exchanger systems with reasonable design, superior performanceand good heat exchange effect, has been widely used in various industries andapplication.

1.Immersion model part heat recovery unit (some of the heat in the recovery system is used

to heat the tap water)

2.Falling film model heat recovery unit(Recover all heat in the refrigeration system, which can

be used as a condenser to achieve dual use)

3.Liquid heat exchange with liquid(clean water heat exchange with tower water or antifreeze)